Scientific Observing Atmospheric Research Balloon

In the spring semester of 2018 in a class called Hands-On Planetary Exploration (HOPE for short), I participated in a project called SOAR: the Scientific Observing Atmospheric Research Balloon. The goal was to launch a high-altitude balloon that would take data about the atmosphere and the land below during its flight and to retrieve the payload and all its data afterwards.

My role in the project was multifaceted. Primarily, I was in charge of all things ADL: Ascent, Descent, and Landing. This meant I was involved in the initial design of the payload itself, in charge of picking a spot to launch from, and most importantly, designing and implementing a cutdown mechanism.

The initial project proposal can be found here. I designed the initial payload designs and made the 3D models, and I was responsible for the initial selection of a secondary cutdown mechanism.

The Cutdown Mechanism

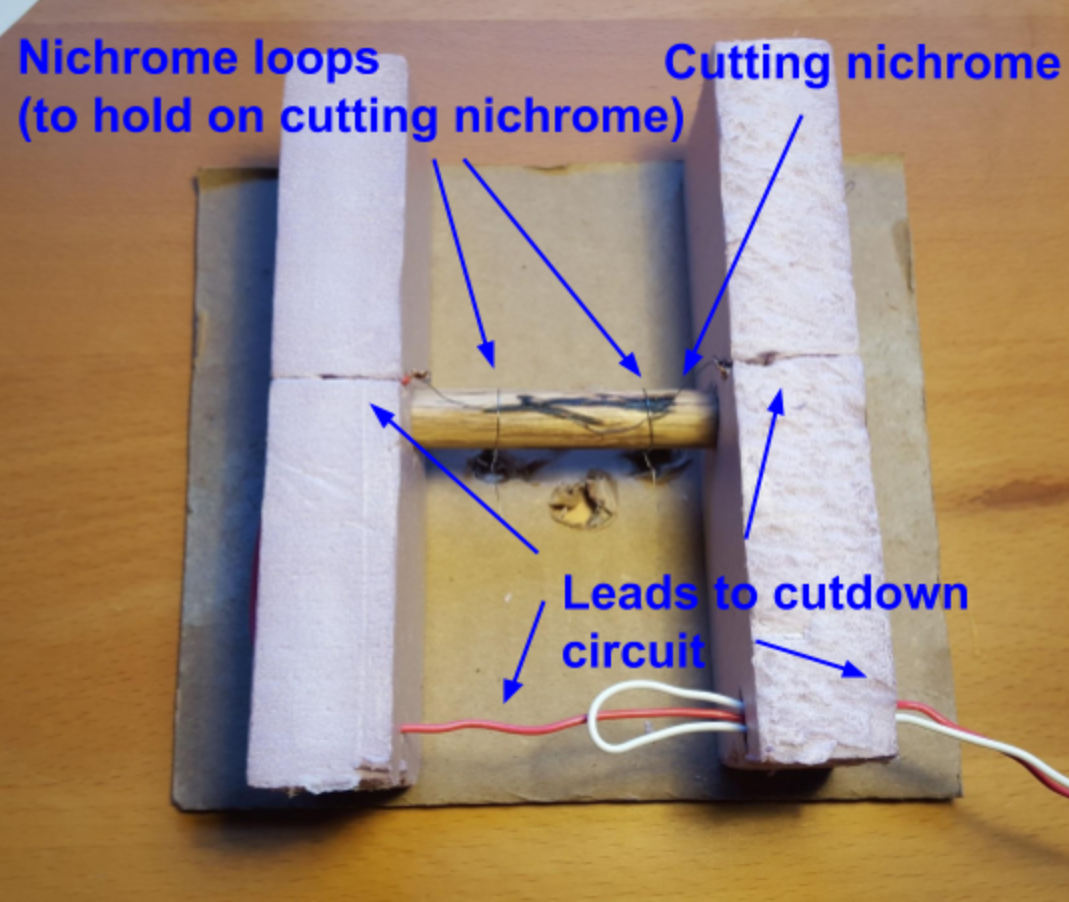

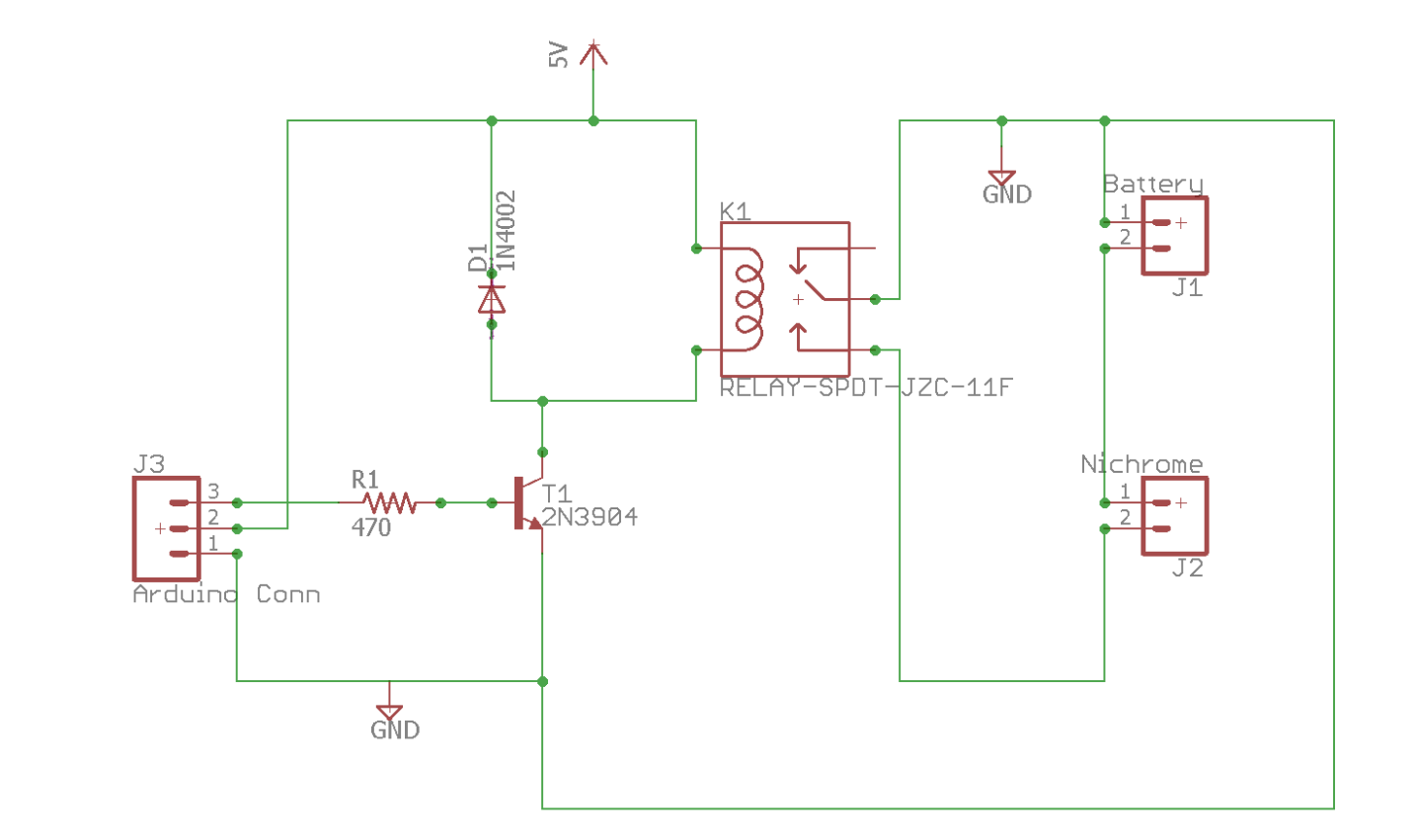

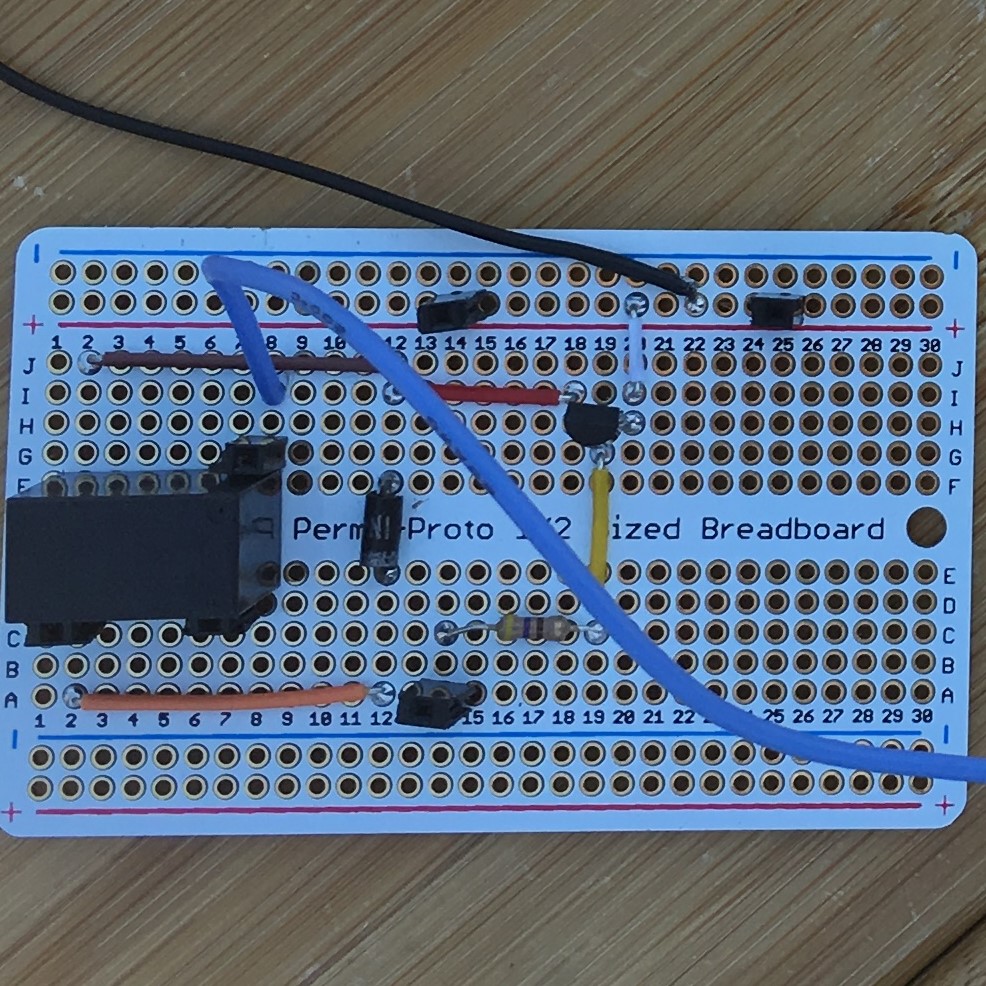

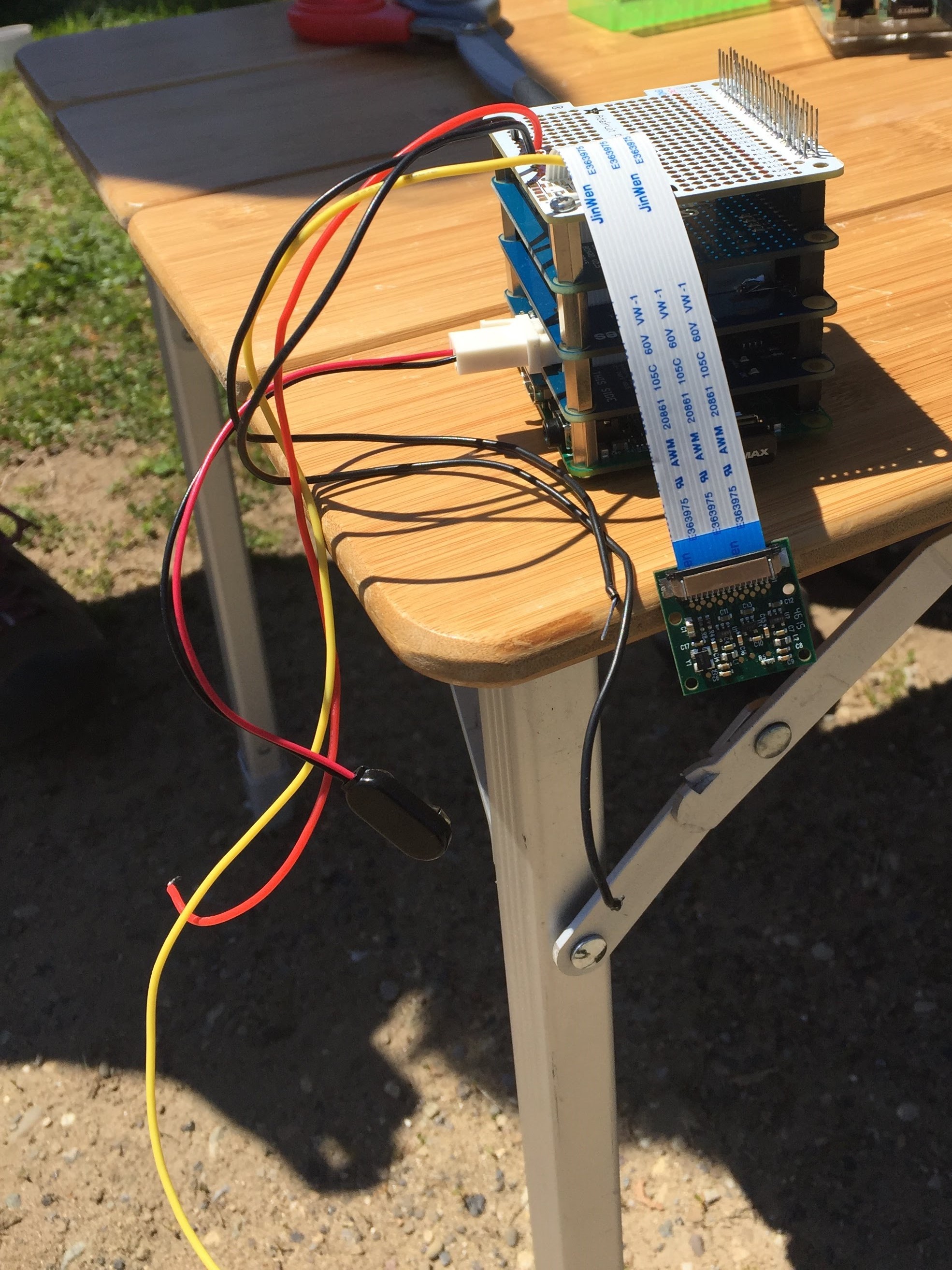

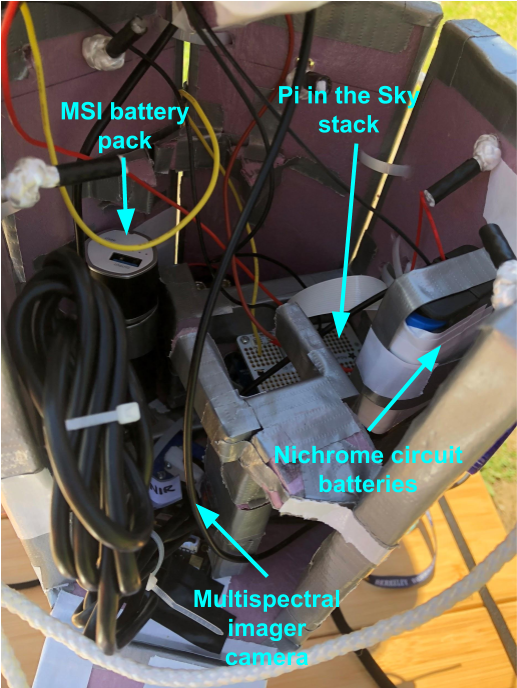

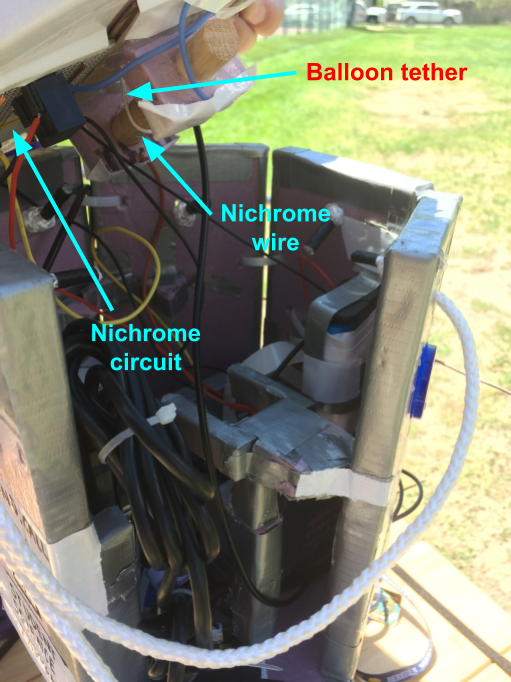

When I started the semester, I had no experience with circuitry. By the end, I had acquired the skills necessary to build a circuit that, controlled by a Raspberry Pi computer, super-heated a nichrome wire enough to melt through nylon rope in a matter of seconds. But let's start at the beginning.

High-altitude balloons (or HABs) are required by law to carry a secondary cutdown mechanism in their payload (the primary mechanism is that the balloon is guaranteed to burst once the atmospheric pressure outside is sufficiently lower than the pressure inside the balloon). There are several options for implementing this, of which the nichrome wire solution is only one. Another that I seriously considered was a pull solenoid, but I eventually rejected the idea for being both too heavy (the total payload weight had to be 2 kg or less) and too expensive.

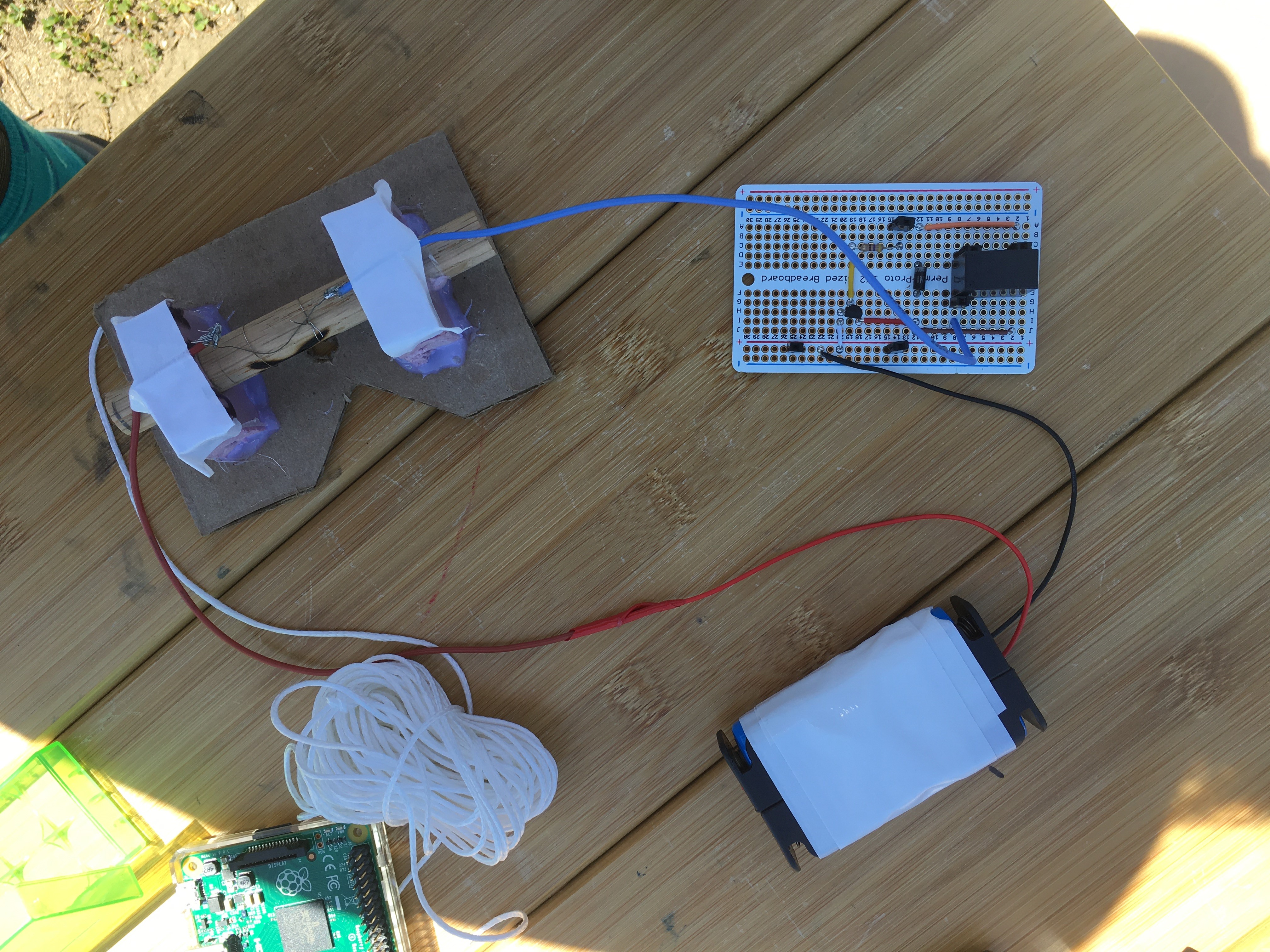

Once all options were considered, I decided to go with a nichrome wire circuit that, when activated by the GPS readout reaching 27,500 meters of altitude, would melt through the tether holding the balloon to the payload. Although it was more complicated to implement than a pull solenoid or prefabricated cutdown mechanism, it was cheaper, lighter, and more flexible than the other options in terms of working with the other systems in the payload.

Working primarily from a circuit design and documentation from White Mountain Science, Inc. (WMSI), I set about building the cutdown circuit in Wellesley's engineering lab. I taught myself what I needed to know about electrical engineering and electromagnetic physics, I learned to solder, and I tested my circuit with both Arduino computers and Raspberry Pis. The process was long and a bit rocky, but ten days pre-launch, the circuit configuration was correct, and a week after that it was working every time.

Other Responsibilities

As I mentioned, I was also involved in designing the payload itself and in selecting a launch site. The latter will be addressed in the "Launch" section, but the former can be explained here.

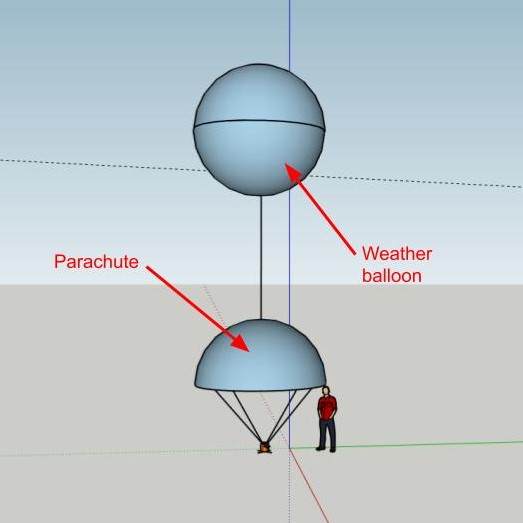

Although the specifics of the design eventually became the responsibility of project manager Jessie Feng, I was heavily involved in the initial stages of the design process and in designing the connection points between the payload and the other parts of the whole: the balloon, the radar reflector (which made the mission more visible to planes), and the parachute.

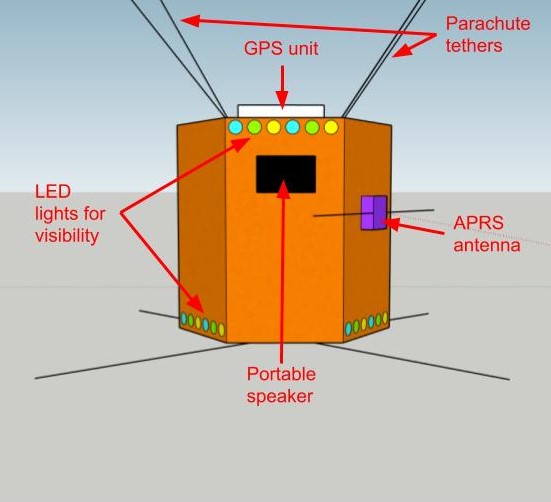

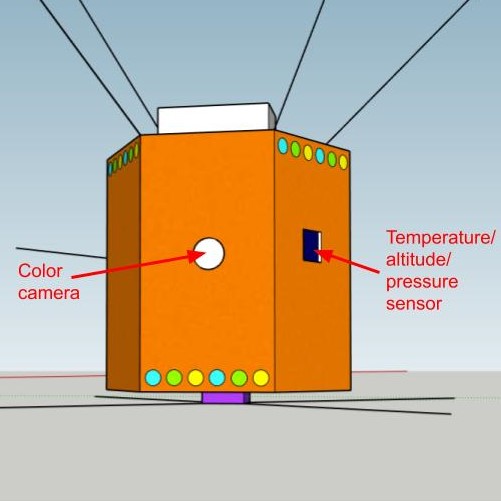

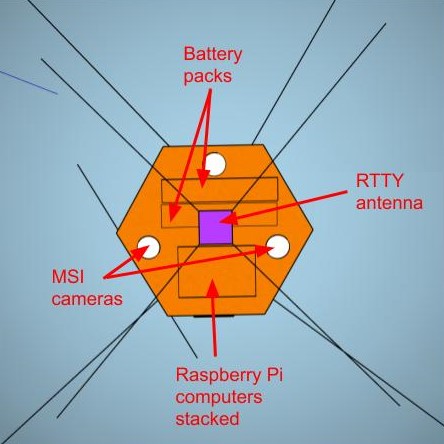

The overall shape of the payload was a hexagonal prism. The idea was to minimize sharp corners on the payload that could take damage or prevent smooth descent through trees at the end of its flight and to maintain feasible construction and maneuverability. The secondary iteration of models for the overall structure are below. (The first iteration's images are in the project proposal presentation.)

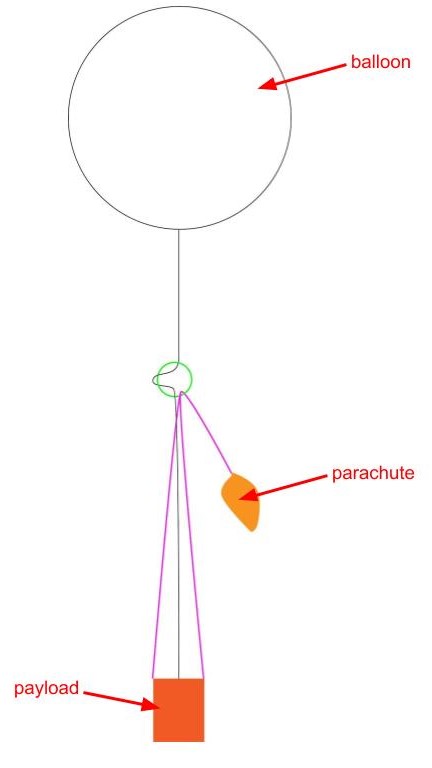

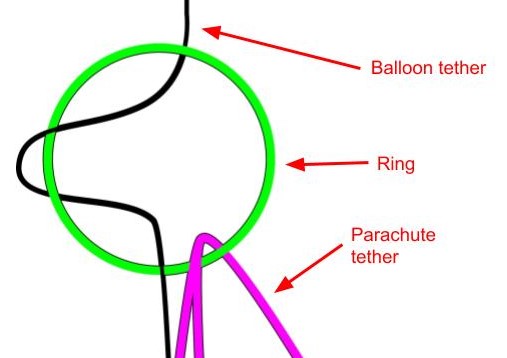

I also worked with Jessie on how to attach the parachute to the rest of the structure. The attachment needed to keep the parachute from dangling under the payload on the ascent, which would interfere with the downward-facing cameras that took data for the multispectral imager built by team member Carol Hundal. The parachute also needed to not be permanently attached to the balloon tether, which would be cut to start the descent; even if the balloon popped before the secondary cutdown mechanism took effect, attaching the parachute directly to the balloon tether could tangle the strings of the parachute and prevent it from opening fully, leaving the payload free to plummet. This is the solution the team came up with:

The inflexibility of the ring that the balloon tether looped through held the ring and therefore the parachute in place when the balloon tether was pulled taught, as it would be during ascent. When the balloon tether was cut, it simply slid out of the ring, leaving the parachute attached to the payload.

Speaking of the parachute, planning for the mission involved a lot of equipment testing - including the parachute. Team member Rebekah Albach and I ran this test by tying a brick of roughly the same weight as the payload to the end of the parachute and tossing it off of the campus parking garage (we were unable to convince the campus Risk Management Office to allow us to throw it off of the taller academic buildings). One of a few tests can be seen below:

Launch

The team launched the balloon on May 12, 2018. An early wakeup was necessary, because the launch site I had decided upon after consulting a flight path simulator, a descent rate calculator, and list of regional airports was Saratoga Springs, NY: 189 miles away from Wellesley. We had to go so far west so that the eastward winds wouldn't blow our payload into the ocean. No one minded much, even though we all worked late the night before. Everyone showed up at the observatory promptly at 6:30 AM to pack the cars. The team had already practiced the launch procedure once before on the previous Tuesday with a test run that kept the balloon tethered to the ground, seen below.

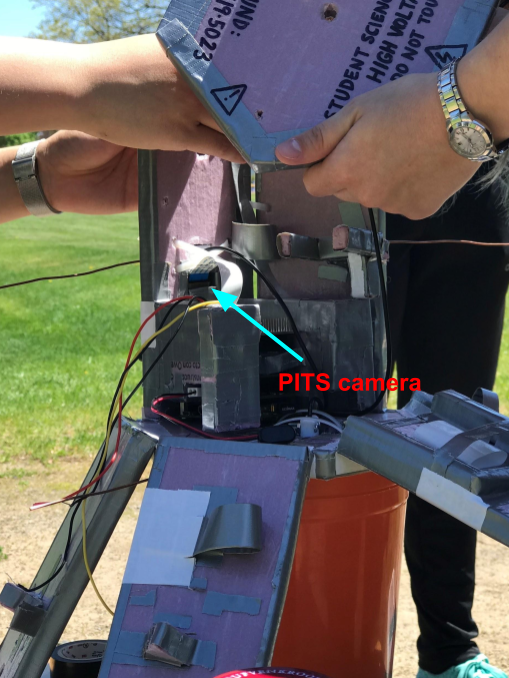

When the team arrived at East Side Recreation Park around 11:00, we weren't the only ones in the park; there was a Little League tournament happening in half of the park, and the park was across from a church on a Sunday morning, all of which is to say: there was an audience. Having anticipated this possibility, we welcomed the curious kids and explained the project as each person prepared for launch. My primary work had finished the previous night with final tests of the circuit's integration with the Pi In The Sky radio stack, so I helped Jessie assemble the parts into the payload, untangled parachute strings, and generally helped wherever I was needed.

The other team members configured the instruments they had built (a multispectral imager and a Geiger counter), inflated the helium balloon, and checked the radio connections. By 2:30, all was ready for launch.

The team moved the balloon and all its associated attachments to an empty part of the park, counted down, and let go.

What followed was a rather dramatic four-state chase of the balloon. The original plan had been for the car I was in to pull up the rear of the chase; we didn't have the long-range receiving equipment or the laptop charging cables the other cars had, so when the other cars peeled out of the parking lot post-launch, my group stayed to clean up, not expecting to be the ones to find the balloon. However, the entire team's radio receivers lost contact with the balloon shortly after the launch, receiving just enough data to be certain that the balloon was rising about half as fast as anticipated, which threw off the projected landing site. Because we had started driving last, when the car I was in (one of three vehicles in the chase) rerouted for Lowell, MA instead of Jaffrey, NH, we had the least course-correction to do. So on we went, pausing only once that day to eat and refill at a gas station in a small town in Vermont.

The other cars were behind ours, but one of them picked up a signal a few hours later that told them the payload had started its descent. This provided another adjustment to the itinerary, rerouting everyone to Nashua, NH. My group arrived in Nashua in the early evening, and decided to sweep the less populated area on the premise that if the payload fell in the middle of town, someone would think to call the phone number printed all over the exterior of the box. Driving around with a laptop on 10% charge and Rocket Man by Elton John playing - as it had during the launch - Rebekah, the Capsule Communications officer, got a signal on RTTY radio, one of the three radio formats she had included on the mission. The signal was a bit scrambled initially, but eventually we received GPS coordinates that put the payload in the middle of a patch of woods. It was all we needed. Plugging the coordinates into Google Maps, we threaded through a neighborhood until we were as close as we could get to the coordinates. All that remained was to scour the forest and find the payload - which we did! But of course, our precious payload was stuck in a tree at least 50 feet off of the ground.

Once the rest of the team arrived, there was a lot of discussion about how to get the payload down, and when that was nixed, how to retrieve the data. The RTTY was transmitting fine, and it could deliver some data, but it could not transmit the photos taken by the onboard camera or the multispectral imager; that required a different radio transmission that was not being received even standing under the tree with the payload. This inspired a few somewhat harebrained schemes to get a receiver closer to the payload in hopes of getting near enough to receive that signal; one such involved me climbing atop another team member's shoulders and holding the receiver in the air, while another idea was to tie the receiver to the top of a smaller, bendier tree than the one holding the payload and then release the tree to spring upright again, radio attached. Neither worked, and in full darkness, there was nothing more we could do, so the team drove back to Wellesley.

A few days later, team members Rebekah Albach and Catherine Nicoloff drove out again with Professor Wes Watters and a very long polesaw to get the payload back.

Although the computers inside were little worse for a night of rain, most of the data was recoverable, including the photos, compiled here.

Exactly four months post-launch, Wellesley College featured the project on their website, with an article that can be found here.

.jpg)